The WTT-Dx, which is waterproof according to an IP67 protection rating, acquires the torque in the axial direction (My) by means of integrated strain gauge sensors. The fully differential design of the strain gauge amplifier, including the bridge feed, ensures maximum interference suppression.

Thanks to the clever design of the sensor housing, the WTT-Dx also delivers high-precision measurement data even during dynamic maneuvering which causes high temperatures. The mechanical stability of the sensor housing is designed to last for multiple vehicle lifetimes of heavy SUVs.

To enable measurements in snow, ice and condensation, the sensor housing, power supply and electronics were integrated into a water-tight (IP67) housing. The special rechargeable batteries installed in the sensor allow measurements at a temperature range of -30 °C to + 60 °C.

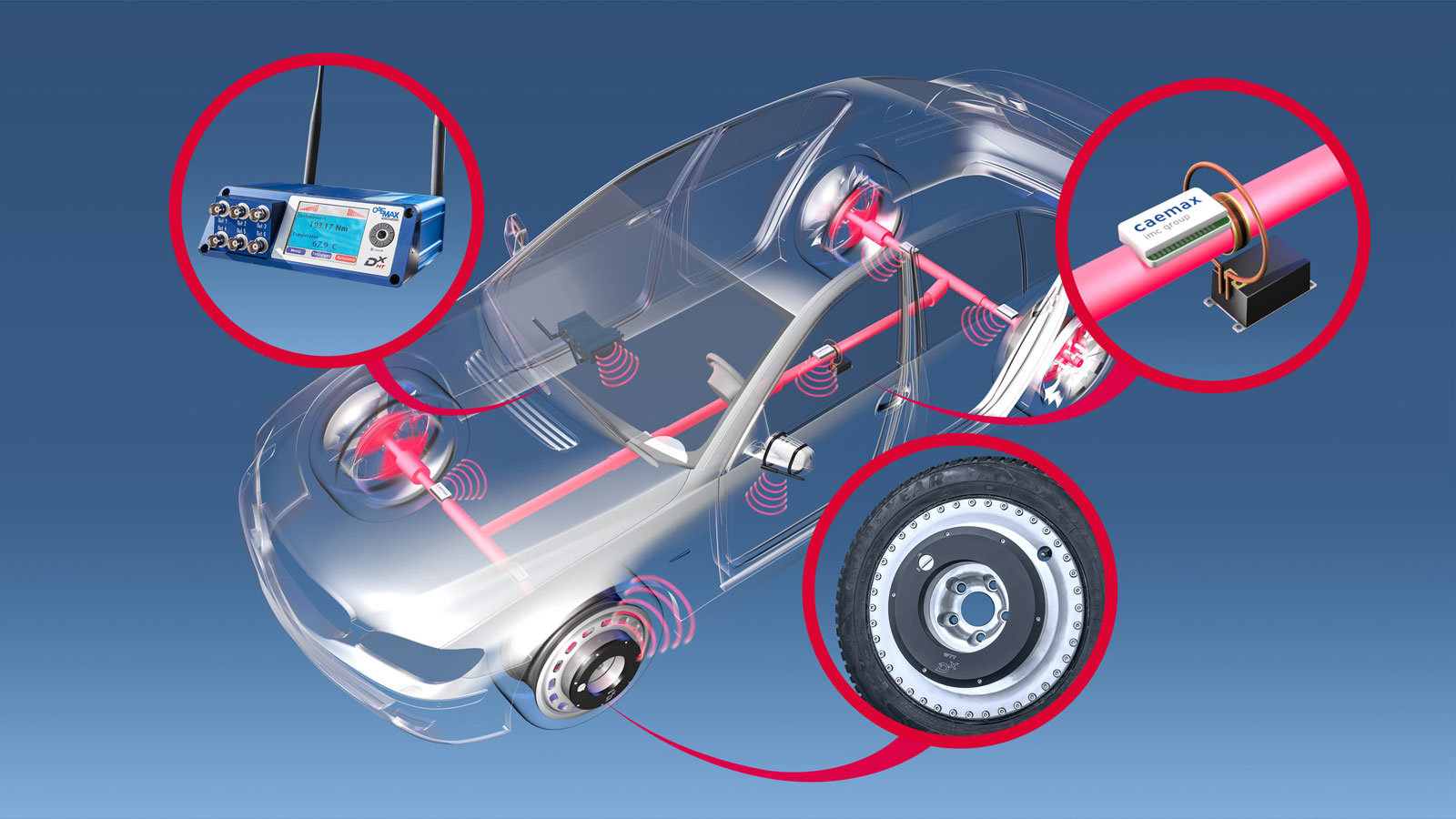

Wireless data transmission

Each WTT wheel torque transducer is equipped with a Dx-telemetry digital transmitter unit. Measurement data from up to four WTTs are transmitted wirelessly from the wheel to receiving antennas on the outside mirrors – thanks to digital technology, interference-free and high-resolution. The Dx-transmitter units integrated in the wheels are centrally controlled and clocked by the receiver unit in the vehicle. This highly simultaneous sampling of all four wheels makes it possible to detect and validate fast control processes between the wheels with high temporal precision. Measurement data are output at the receiver unit via CAN or analog and can therefore be easily integrated into existing measurement systems.

Drivetrain efficiency optimization

In order to reduce energy consumption and CO2 emissions of vehicles, drivetrain efficiency is investigated during automotive development and continuously improved. For measurements on the drivetrain, the WTT-Dx precisely acquires the torques directly acting upon the wheels. Additional measurement variables are acquired parallel, and these combined data are used to quantify and model efficiency and friction losses along the drivetrain.

Testing driving dynamics in winter

During winter testing, the vehicle, test engineer and measurement equipment are not only exposed to snow and ice but also to high temperature fluctuations and melt water. The waterproof (IP67) and robust WTT-Dx proves its worth in these harsh environmental conditions: replaceable cold-climate batteries enable the system to be used at ambient temperatures down to -30 °C. The resistive sensor body is designed for mechanical loads up to ± 6 kNm. The simple assembly and operation enable a fast and uncomplicated exchange of components.During winter testing, the vehicle, test engineer and measurement equipment are not only exposed to snow and ice but also to high temperature fluctuations and melt water. The waterproof (IP67) and robust WTT-Dx proves its worth in these harsh environmental conditions: replaceable cold-climate batteries enable the system to be used at ambient temperatures down to -30 °C. The resistive sensor body is designed for mechanical loads up to ± 6 kNm. The simple assembly and operation enable a fast and uncomplicated exchange of components.

Evaluation of driving assistance systems

In order to optimize traction, maneuverability and directional stability, modern all-wheel-drive vehicles regulate the distribution of drive torque to the wheels within milliseconds. Thus, wheel torque transducers that are used for the evaluation of driving assistance systems must record measurements with high temporal precision. With the WTT-Dx, all four wheel torque transducers are sampled synchronously and in high temporal resolution. The interference-free transmission (diversity-mode) minimizes signal failures.

Suitable for many different vehicle types

With the CAEMAX adapter system, WTTs can be mounted with minimum effort on different vehicle types. The WTT sensor housing, telemetry module and adapter can be combined as desired. This covers a wide range of wheel sizes and vehicles. A quick system set-up and convenient software functions, such as zero calibration, allow the system to be test-ready within a very short time.

- Rim adapter:

As with a conventional rim, the rim adapter serves as a mount for the tire. The rim adapter is not directly specific to the vehicle, but depends on the tire. This allows it to be used on different vehicles with the same tire size.

- Hub adapter:

The hub adapter is used to connect the WTT-Dx to the vehicle. It can be used for different types of vehicles, as long as the bolt circle and the wheel offset are the same. With just a few hub adapters, an entire fleet of vehicles can be covered.

- WTT-Dx sensor housing:

The sensor housing connects the hub adapter and the rim adapter to each other.

Thus, based on a modular design, a WTT-Dx wheel torque transducer can be adapted to the vehicle in a time-saving, space-saving and cost-effective manner.

Test-ready in just an hour

The installation of a WTT-Dx is almost as easy as a wheel change – four WTTs can be mounted in one hour. Thanks to an uncomplicated system set-up and convenient software functions, such as the zero calibration, the system can be test-ready within a very short time.

WTT-DX wheel torque transducer

| Parameter |

Value |

| Measurement value |

torque in axial direction My |

| Signal transmission |

digital-telemetric |

| Measurement range |

My = 8,75 ±6000 Nm, optional, My = ±3000 Nm |

| Bandwidth |

max. 1 kHz |

| Linearity |

< 0.5 % |

| Hysteresis |

< 0.5 % |

| Crosstalk |

< 0.5 % |

| Sensor diameter |

300 mm |

| Sensor weight |

ca. 4.75 kg (incl. telemetry unit)

ca. 6.3 kg (with battery) |

| Sensor housing material |

aluminum |

| Mechanical load |

stress analysis according to AK-LH-08 4.34 |

| Rim diameter |

min. 13″ |

| Hub diameter with adapter |

max. 6″ |

| Operating temperature |

-10° C up to +60° C (standard battery)

-30° C up to +60° C (special battery) |

| Max. driving speed |

250 km/h |

| Max. rpm |

2300 rpm |

| Shock proof |

100 g |

| Protection rating |

IP67 (waterproof) |

| Mounting and balancing |

yes (wheel bolts accessible) |

| Power supply |

standard battery: up to 80 h

special battery: up to 40 h |

| Telemetry properties |

Value |

| Power supply |

9 to 36 V DC |

| Power consumption |

< 5 W |

| Frequency |

freely-configurable in the 868 MHz band (optional 2.4 GHz) |

| Synchronization |

synchronized sampling of up to 4 WTTs |

CAN output (connection according to ISO 11898,

galvanically isolated) |

CAN 2.0b, standard & extended-identifier,

freely-programmable up to max. 1 MBaud |

| Analog output |

6 x BNC sockets, (freely-assignable, output signal max. ±10 V) |

| Ethernet |

10/100 Mbit |

| Auto-zero |

remote-controllable |

| Temperature range |

-20 °C up to +65 °C |

| Dimensions |

ca. 170 mm x 130 mm x 53 mm |

| Weight |

0.8 kg |

![[:vi]Bộ chuyển đổi mô-men xoắn bánh xe WTT-Dx (Không ảnh hưởng bới thời tiết • mạnh mẽ • không dây) [:en]Wheel Torque Transducer WTT-Dx (weatherproof • robust • wireless)[:]](https://amescovn.com/wp-content/uploads/2021/08/2021-08-09_12-03-51.png)

Gọi điện

Gọi điện SMS

SMS Chỉ Đường

Chỉ Đường