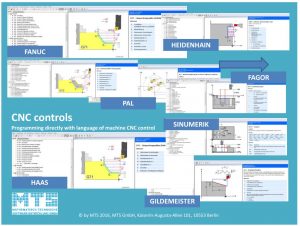

The programming language of an ISO6983/DIN66025 CNC control is defined by its command codes. Unfortunately, these command codes have developed in different directions becoming incompatible between each other because of the freedoms of the very old ISO/DIN standards.

The special feature of the MTS CNC simulation software TopTurn and TopMill is that it can be adapted to the command coding of any industrial control according to ISO6983/DIN66025 and this is even the case with some non-ISO/DIN-oriented command codings of the so-called “dialog controls”.

For program generation, a universal dialog programming with entry forms for the G commands and control-dependent canned cycles of the respective command coding is available in the NC editor. The commands are supported by appropriate auxiliary graphics.

For certain control families, the parameter programming can also be offered in these command codings. The CNC control syntax can be individually adapted and extended to customer requirements.

For the simulation of CNC control-specific command codes MTS uses internally a comprehensive CNC command coding, which contains almost all existing canned cycles.

Adaptations to all common CNC controls have already been implemented. More information about this concept can be seen in the NC program examples for different control codings of our demo version.

![[:en]CNC Controls[:]](https://amescovn.com/wp-content/uploads/2021/08/212.jpg)

Gọi điện

Gọi điện SMS

SMS Chỉ Đường

Chỉ Đường