Description:

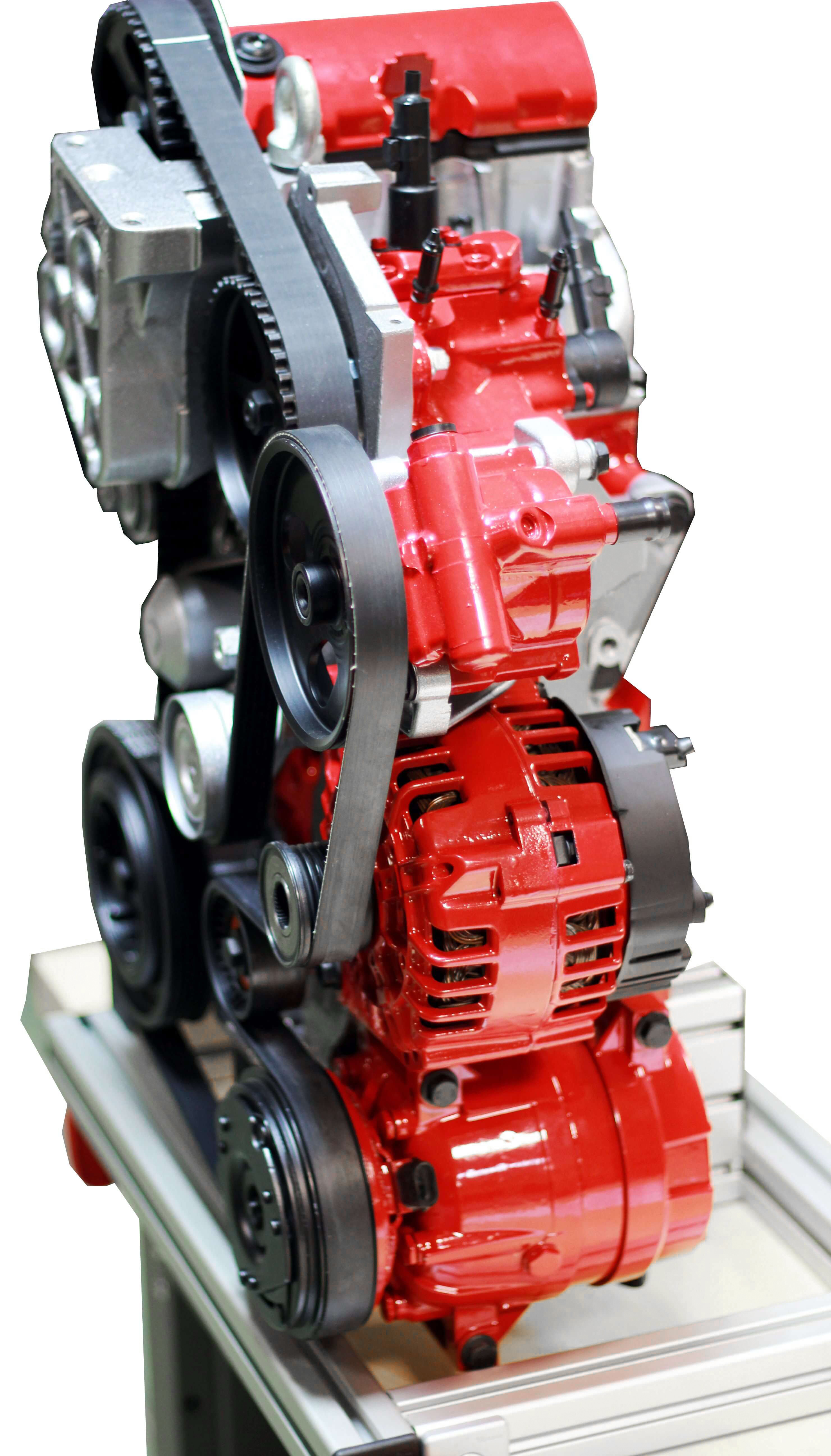

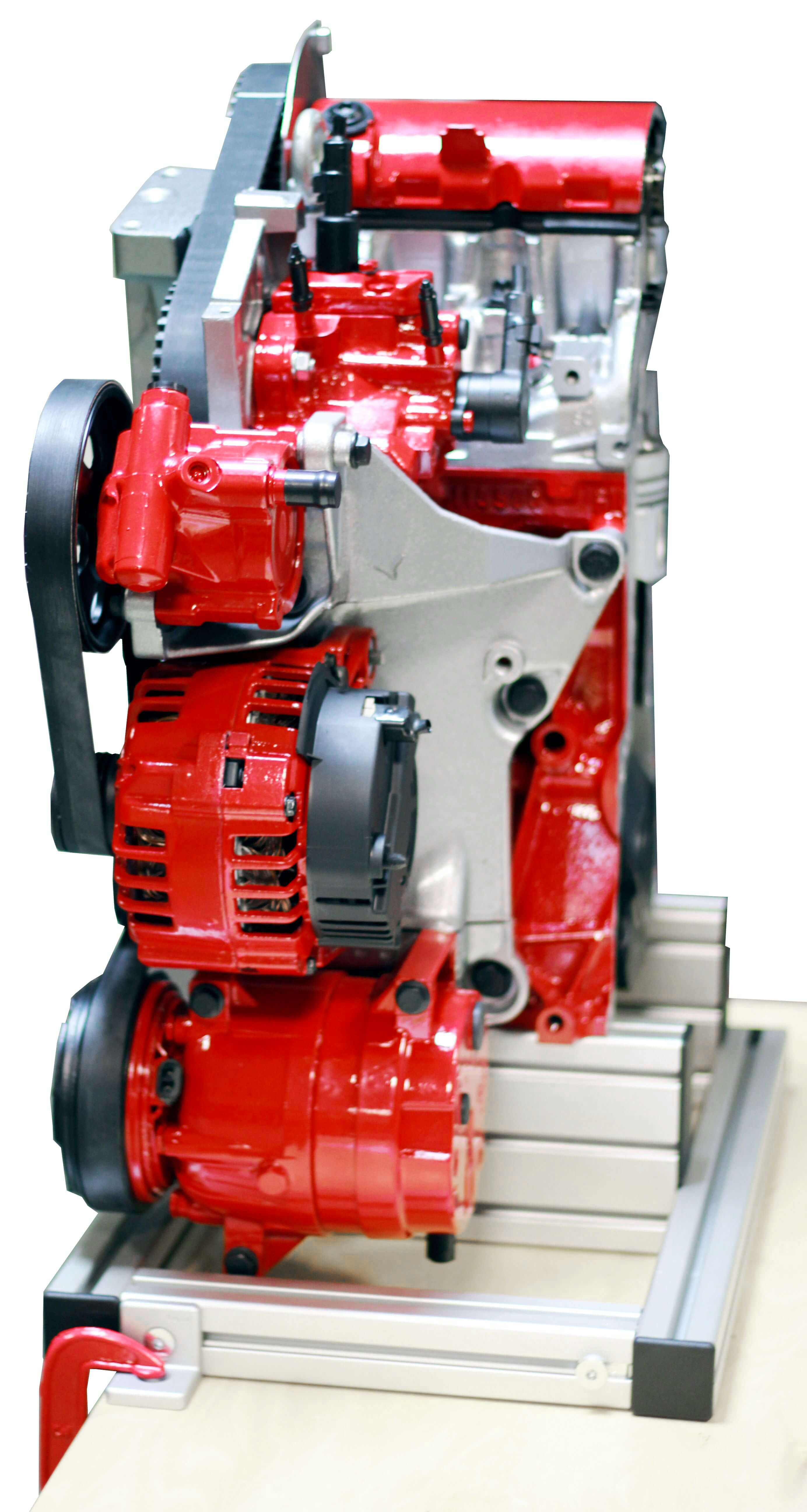

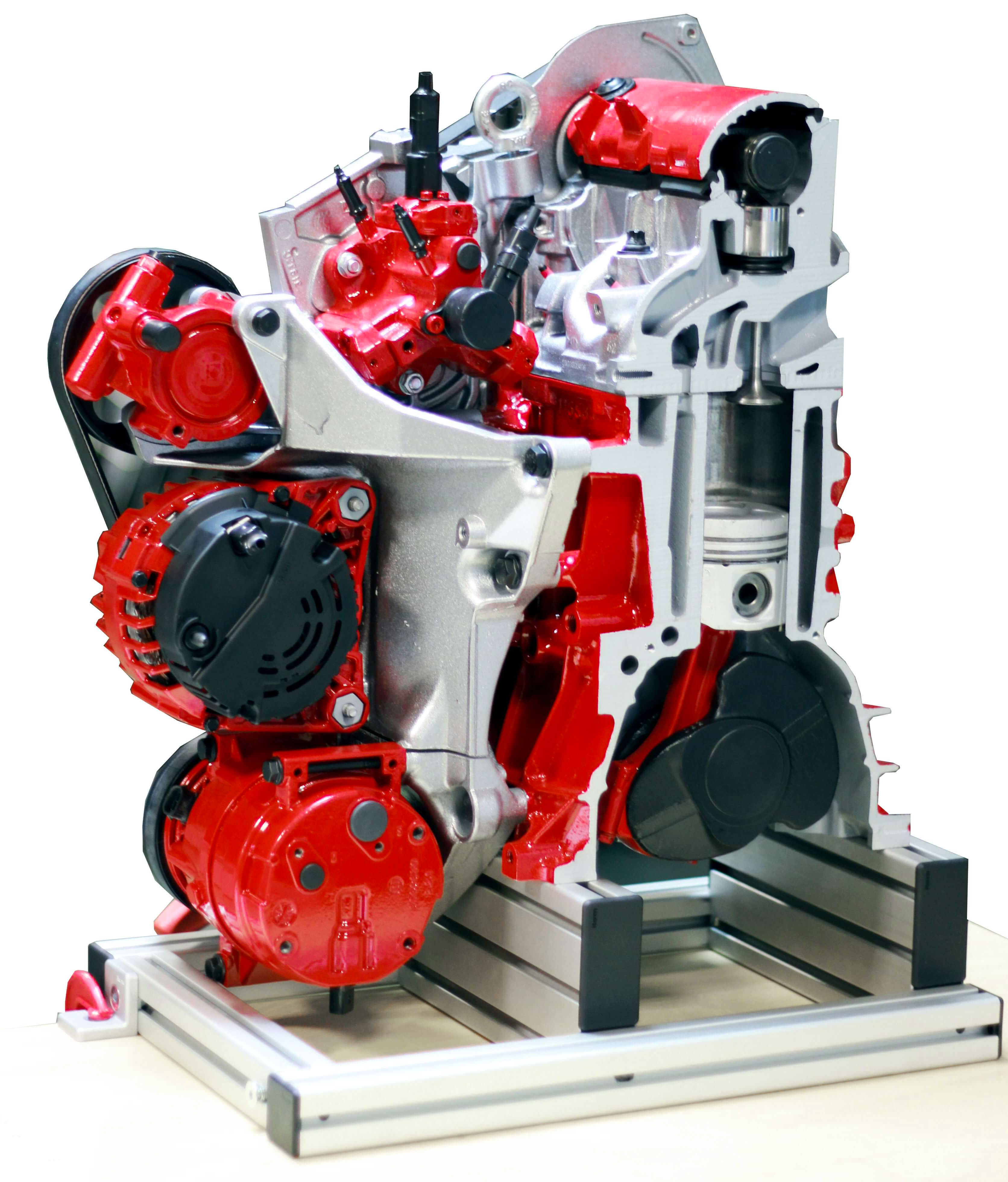

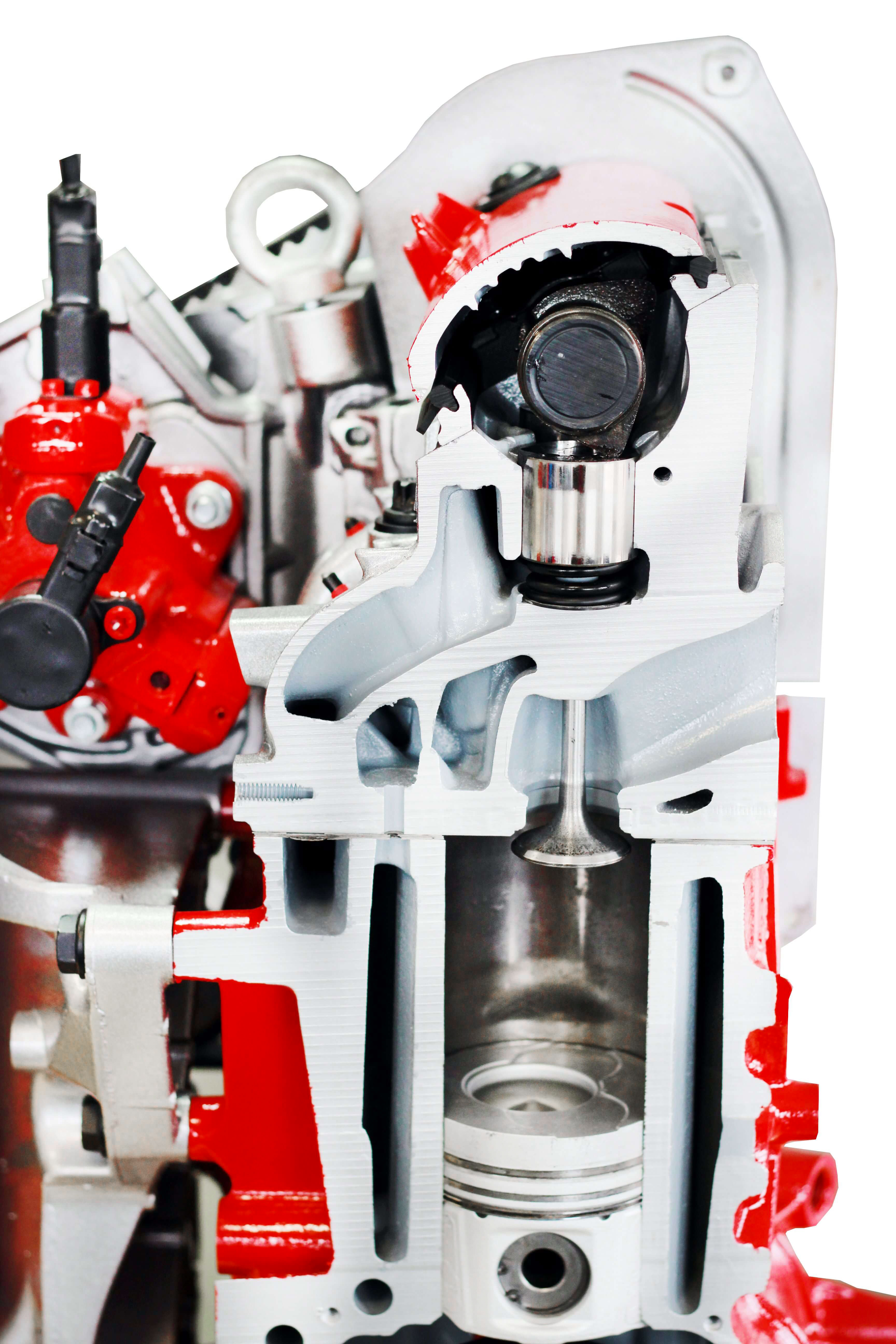

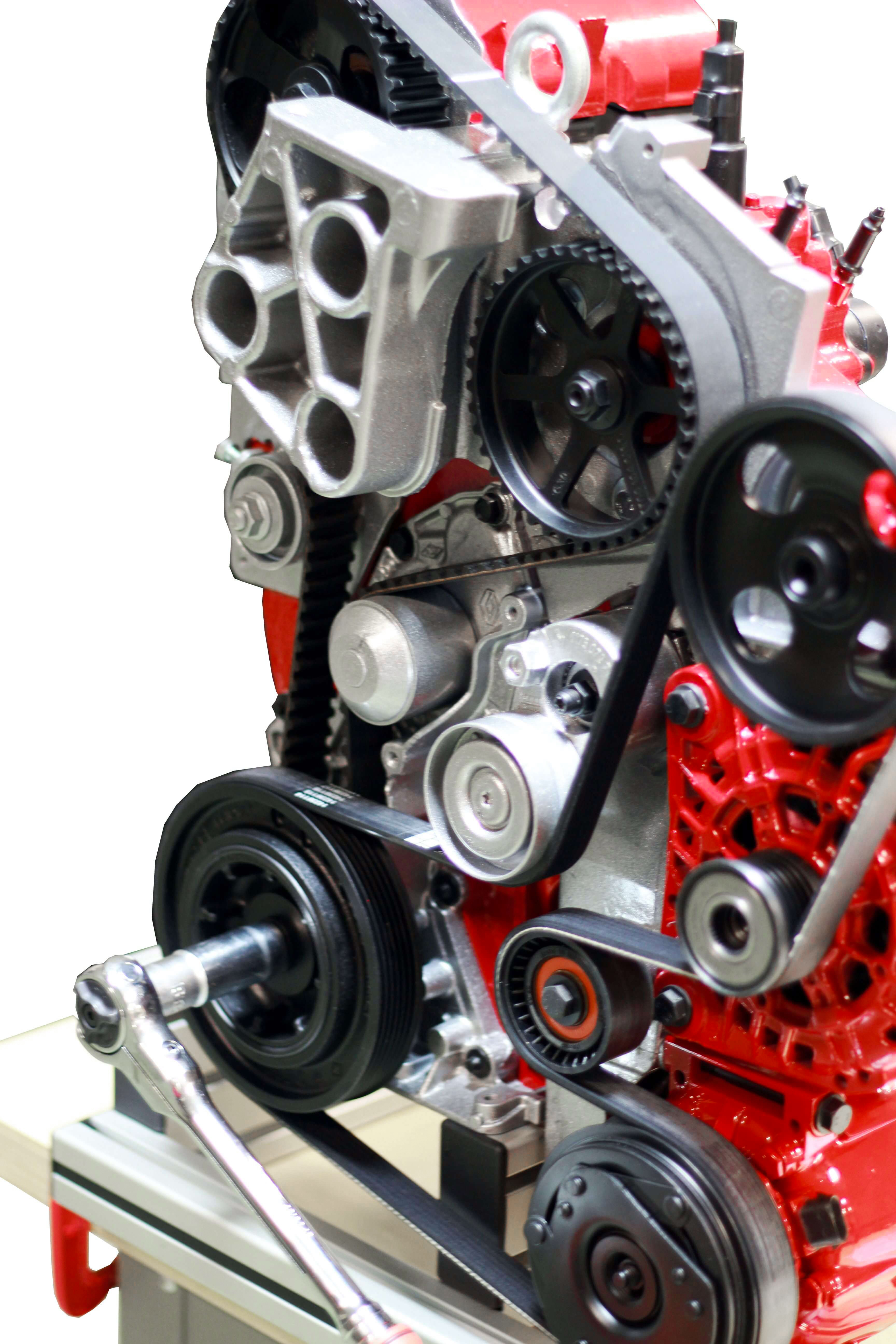

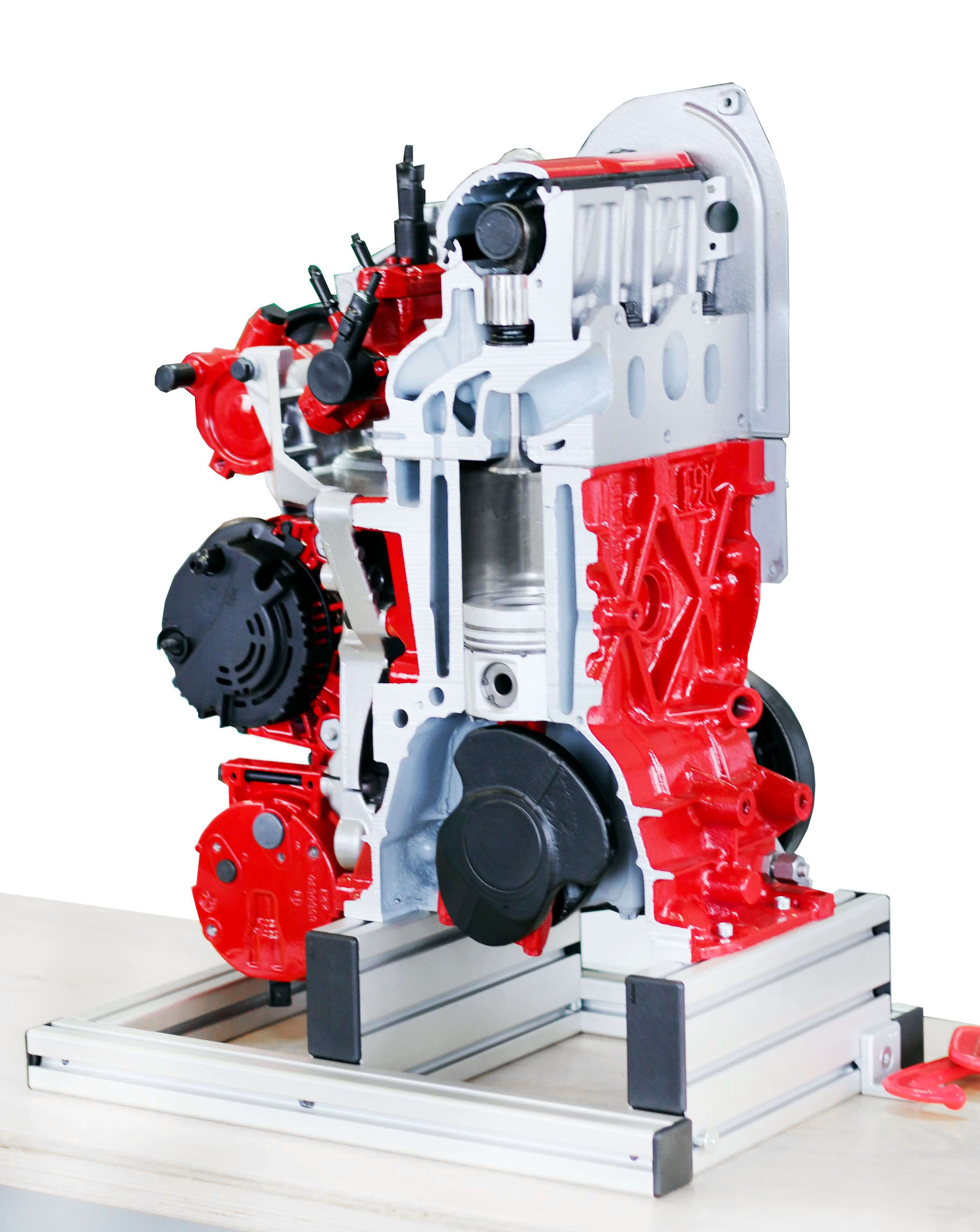

Diesel OHC Common Rail engine, featuring a sectioned view of engine block, crankshaft, OHC camshaft with valves, pistons with rings, and a high-pressure CR pump. The model allows hands-on training in timing belt and alternator belt replacement, using specialized tools for torque measurement. The trainer’s cutaway design enables the examination of piston operation, combustion chamber dynamics, and the OHC mechanism, all while ensuring safety with protective plastic covers. Compact and portable, it is ideal for use in technical and vocational automotive education.

Features

- Provides a detailed view of key engine components, including the engine block, crankshaft, OHC camshaft, pistons, and combustion chamber.

- Facilitates practical training in timing belt and alternator belt replacement with visible tensioners and camshaft sprocket.

- Allows for the manual operation of the crankshaft to demonstrate OHC mechanics and component movements.

- Equipped with safety protection to ensure a safe training environment.

- Lightweight design with bench clamps for easy placement on workbenches or tool trolleys.

Value for Students

- Understand key engine components, including the engine block, crankshaft, OHC camshaft with valves, pistons with rings, and high-pressure CR pump. These insights are critical for grasping the fundamentals of diesel engine operation.

- The model facilitates practical training in timing belt and alternator belt replacement, offering a realistic experience in handling and replacing these essential components. Special tools provided with the trainer allow for torque measurements, enhancing the precision of hands-on learning.

- By manually turning the crankshaft, students can observe the operation of the OHC mechanism, including the movement of pistons and the functioning of the combustion chamber. This practical exposure is crucial for understanding the timing and synchronization of engine components.

- The cutaway design, coupled with safety protection, ensures that all training is conducted in a safe environment.

- Visible sections of the engine allow students to clearly see the combustion chamber, intake and exhaust ports, injector, and glow plug positions without exposure to operational hazards.

Value for Instructors

- Provides easy, safe, and comfortable training that builds confidence, using OEM components to offer a realistic truck repair experience.

- This fully sectioned allows instructors to clearly demonstrate the internal workings of a diesel engine, including the timing and alternator belt replacement processes. The visible components facilitate easy explanation and ensure that students can follow along with complex concepts.

- The compact and lightweight design of the trainer makes it easy to integrate into various classroom setups. It can be placed on a workbench or tool trolley, minimizing the need for additional space or mounting stands.

- Designed for educational purposes, this model is robust and requires minimal maintenance. The provided special tools simplify the preparation for each training session, allowing teachers to focus on instruction rather than setup.

Specifications

- Dimensions: 650 x 600 x 320 mm (25.59 in x 23.62 in x 12.60 in)

- Weight: approx. 75 kg (165 lb)

- Tools Included: special tool kit for timing belt replacement

- Product number: IVOD01-CR01

![[:en]Diesel engine ½ cutaway model IVOD01-CR01 AutoEDU[:]](https://amescovn.com/wp-content/uploads/2025/01/IVOD-CR01-1.jpg)

Gọi điện

Gọi điện SMS

SMS Chỉ Đường

Chỉ Đường